The Future of Baggage Handling Systems (BHS) in Germany

Germany, the land of innovation and precision engineering, is a global leader in airport technology. This reputation extends to their airport baggage handling systems (BHS), renowned for their efficiency, reliability, and cutting-edge features. Whether you’re a frequent flyer or an aviation enthusiast, understanding the intricate world of German BHS will shed light on the smooth operation behind your next seamless travel experience.

The German BHS Landscape

German airport BHS encompass a complex network of integrated components, each playing a vital role in the choreography of baggage movement. Here’s a closer look at the key elements:

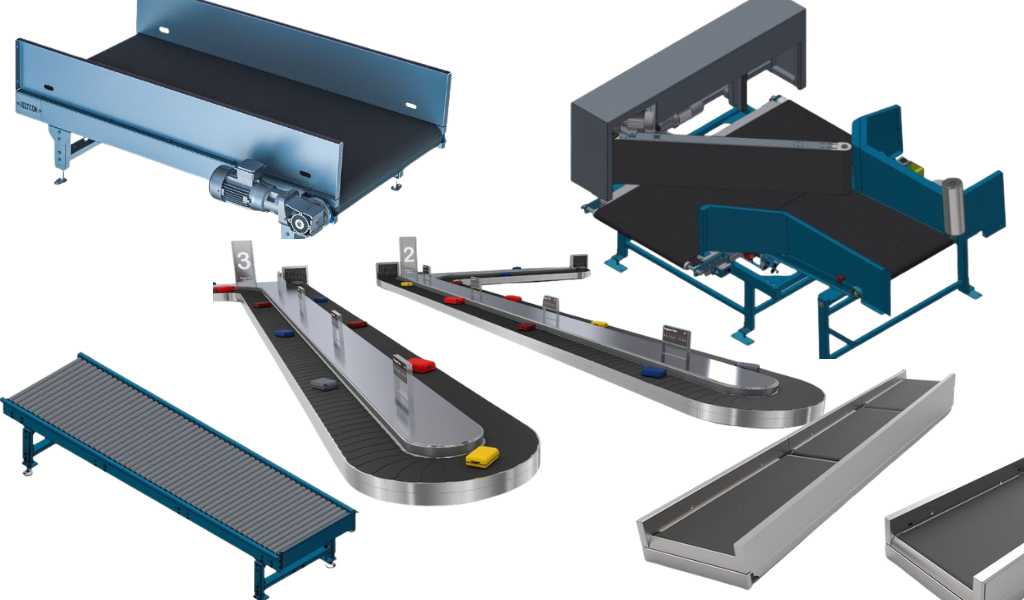

Airport Baggage Conveyor Systems: The workhorses of the BHS, these conveyor belts efficiently transport checked luggage from check-in counters to sorting areas, ultimately delivering them to the correct departure aircraft. Germany boasts expertise in high-speed conveyor systems, ensuring swift and reliable baggage handling.

BHS Sorting Systems: The heart of the BHS, sorting systems determine the final destination of each suitcase. Tilt-tray sorters are a popular choice in Germany, utilizing angled trays that tilt to gently guide baggage down designated chutes. Other advanced sorting technologies include shoe sorters and vertical sorters, catering to various baggage volumes and airport layouts.

Automated Baggage Handling Equipment: German airports are increasingly embracing automation to enhance efficiency and reduce manual labor. This includes automated baggage loaders and unloaders, which seamlessly transfer luggage between conveyor belts and containers. Automated Guided Vehicles (AGVs) further add a touch of futuristic efficiency, transporting baggage containers autonomously throughout the airport.

Baggage Claim Systems: The final touchpoint for arriving passengers, baggage claim systems ensure a smooth retrieval process. Baggage claim carousels, a familiar sight in airports worldwide, are a staple of German BHS. Advanced carousels boast features like integrated security screening and weight limits for smoother baggage handling.

Cargo Handling Systems: While passenger baggage receives the most attention, German airports also excel in cargo handling. Sophisticated conveyor systems, often designed for heavier loads, efficiently transport cargo shipments within the airport, ensuring timely deliveries.

German BHS Technology

German BHS manufacturers are constantly pushing the boundaries of innovation. Here are some exciting advancements taking center stage:

Early Baggage Storage (EBS): This system allows airlines to store checked luggage well in advance of departure, freeing up valuable space at check-in counters and improving operational efficiency.

In-Line Screening Systems (ILS): Integrated directly into the BHS, ILS enable real-time baggage screening without diverting luggage flow. This not only enhances security but also streamlines the baggage handling process.

Automated Baggage Handling Systems: As mentioned earlier, automation is a major focus in German BHS. Fully automated systems are capable of handling baggage with minimal human intervention, leading to faster processing times and reduced operational costs.

Robotics in Baggage Handling: Robots are making their way into German BHS, performing tasks like baggage sorting and palletizing. This integration of robotics further increases efficiency and accuracy.

AI-powered BHS: Artificial intelligence (AI) is revolutionizing BHS by optimizing baggage routing, predicting potential bottlenecks, and even performing predictive maintenance. AI-powered BHS offer unparalleled levels of efficiency and reliability.

A Benchmark for the World

German airport BHS are renowned for their efficiency, a cornerstone of German engineering. Here’s how they achieve this remarkable feat:

High-Quality Manufacturing: German BHS components are built with meticulous attention to detail, utilizing top-grade materials for exceptional durability and reliability.

Modular Design: German BHS are designed with a modular approach, allowing for easy customization and scalability to cater to the specific needs of each airport.

Energy Efficiency: Sustainability is a major concern in today’s world. German BHS manufacturers prioritize energy-efficient technologies, reducing operational costs and environmental impact.

Safety and Security: Safety is paramount in German BHS. Advanced safety features are integrated throughout the system, ensuring the safe handling of baggage and protecting personnel.

The Future of German BHS

The future of German BHS is brimming with exciting possibilities. Here are some trends to watch:

Biometric Baggage Identification: Imagine a future where baggage is tagged with biometric identifiers for seamless tracking and faster processing. This technology is on the horizon, and German manufacturers are at the forefront of its development.

Enhanced Security Measures: Security remains a top priority in aviation. German BHS will continue to evolve with advanced security features like explosive detection systems

Pricing Table for Baggage Handling Systems

It’s important to understand that due to the complex and customized nature of Airport Baggage Handling Systems (BHS), providing a single price table isn’t entirely feasible. The cost of a BHS depends on a multitude of factors, including:

- System Size and Capacity: The number of passengers and baggage volume an airport handles significantly impacts BHS pricing. A large international airport will require a more extensive and expensive system compared to a regional airport.

- Level of Automation: Highly automated systems with features like robotic sorters and AGVs will naturally cost more than semi-automated or manual systems.

- Specific Components: The types of sorting systems (tilt-tray, shoe sorter, etc.), conveyor belt lengths, and the number of baggage claim carousels all influence the overall price.

- Customization: Airports with unique layouts or specific needs may require custom-designed BHS elements, driving up the cost.

However, to give you a general idea, here’s a breakdown of estimated price ranges for some common BHS components:

- Standard conveyor belt system: EUR 500,000 – EUR 1,500,000

- Automated sorting gates, barcode scanners: EUR 800,000 – EUR 2,000,000

- X-ray machines, explosive detection systems: EUR 1,000,000 – EUR 3,000,000

- Carousel systems, digital displays: EUR 300,000 – EUR 1,000,000

- Integration services, software development: EUR 500,000 – EUR 1,500,000

Get a Quote from Top 6 Global Leader BHS Manufacturers

FAQs

Are German BHS expensive?

While German BHS are known for their high quality and advanced features, the cost can vary depending on the size and level of automation needed for your airport. However, their efficiency and durability often lead to a lower total cost of ownership in the long run.

What are the benefits of German BHS?

German BHS offer a winning combination of efficiency, reliability, and innovative technology. They excel in fast baggage handling, advanced security features, and modular designs that adapt to your airport’s specific needs.

What are some future trends in German BHS?

The future of German BHS is exciting! Look out for advancements like biometric baggage identification, enhanced security measures, and even greater integration of robotics and AI for a seamless and secure baggage handling experience.